Advanced Mineral Processing Equipment Enhancing Safety and Productivity

In the ever-evolving field of mineral processing, the advent of advanced equipment has marked a significant leap forward, enhancing both safety and productivity in mining operations. The integration of state-of-the-art technology has transformed traditional practices, ensuring that operations are not only more efficient but also safer for workers and the environment. One of the foremost advancements in mineral processing is the development of automated and remotely operated machinery. These innovations allow for the operation of processing equipment from a safe distance, significantly reducing the risk of accidents and injuries. For example, automated crushers and grinders, which once required direct human oversight, can now be monitored and controlled through sophisticated control systems. This shift not only minimizes human exposure to hazardous conditions but also improves precision and consistency in processing.

Another critical advancement is the enhancement of process monitoring and control systems. Modern mineral processing equipment is equipped with real-time sensors and data analytics capabilities that provide continuous feedback on the operational status of machinery. These systems can detect anomalies, predict maintenance needs, and optimize processing parameters to ensure maximum efficiency. By leveraging big data and machine learning algorithms, these technologies help in preemptively addressing potential issues before they escalate into significant problems, thereby reducing downtime and enhancing productivity and Recommended Site www.minejxsc.com. In addition to automation and advanced monitoring, the development of more efficient separation technologies has revolutionized the mineral processing industry. Techniques such as advanced flotation systems and high-efficiency classifiers enable more precise separation of valuable minerals from waste material. This not only improves the yield of valuable resources but also reduces the volume of waste generated, leading to more sustainable practices. The use of these technologies aligns with the industry’s growing emphasis on environmental stewardship and resource conservation.

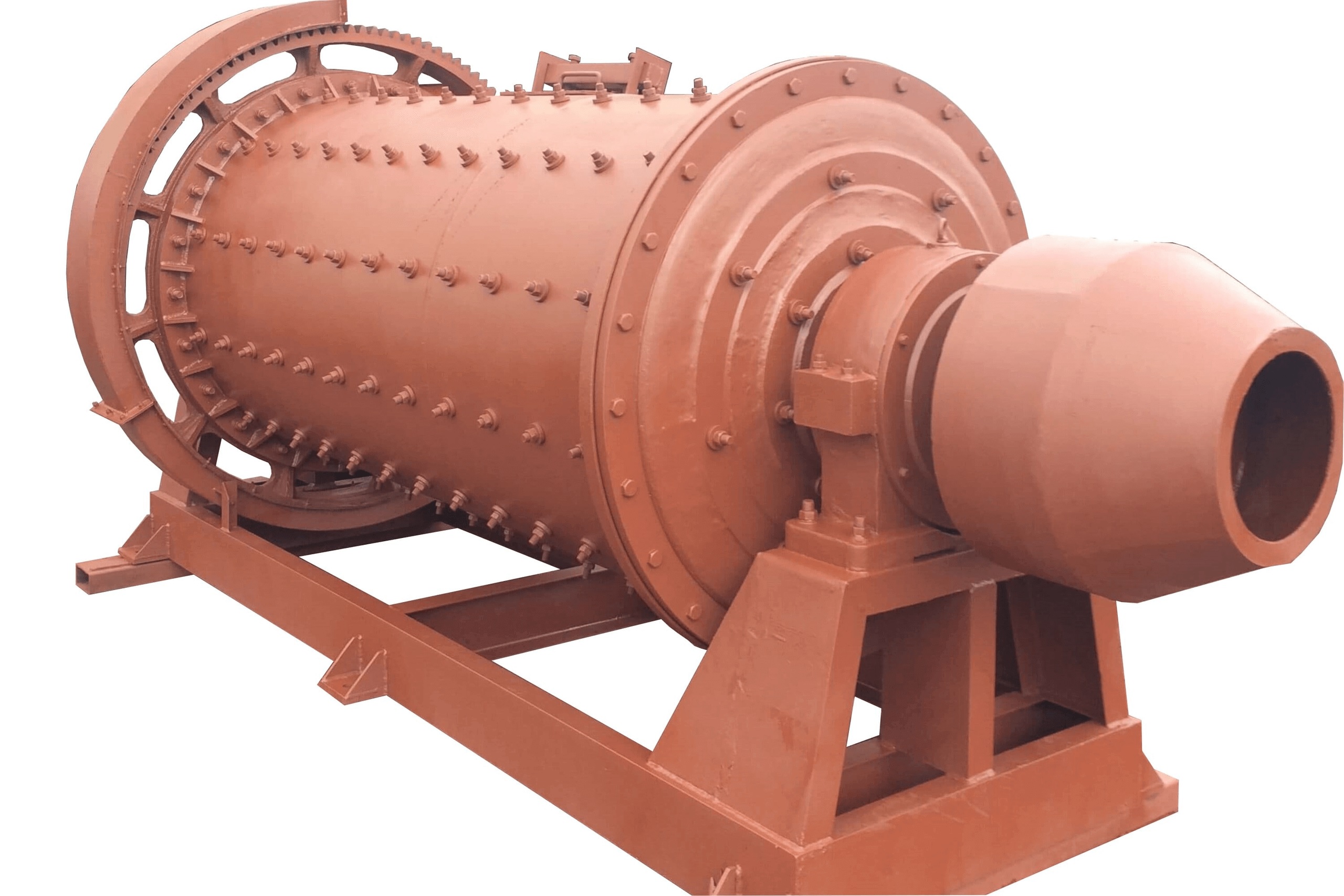

Safety enhancements have also been a focal point in the evolution of mineral processing equipment. Modern machinery is designed with robust safety features, including advanced hazard detection systems, emergency shut-off mechanisms, and ergonomic controls. These features are intended to protect workers from potential hazards such as equipment malfunctions or unsafe operating conditions. Additionally, the implementation of virtual reality VR and simulation training programs allows operators to gain hands-on experience in a controlled environment, further reducing the risk of accidents in real-world operations. The integration of sustainable practices in mineral processing is another area of significant progress. Advanced equipment now incorporates energy-efficient technologies and systems that reduce the environmental footprint of mining operations. Innovations such as energy-efficient motors, improved material handling systems, and what is a ball mill waste heat recovery solutions contribute to lower energy consumption and reduced greenhouse gas emissions. This focus on sustainability not only supports regulatory compliance but also enhances the industry’s social license to operate.

Recent Posts

- Protect Your Collection’s Future With TAG Graded Slabs

- Eco-Friendly Aligners: Invisalign’s Journey Towards Sustainable Dentistry

- Choose Safe Asbestos Removal for a Healthier, Worry-Free Future

- Flexible Packaging Options Support Innovative Branding and Customer Engagement

- Step-by-Step Guide: iPhone 11 Pro Max Battery Removal Made Easy