Latest Posts Under: Business

In today’s environmentally conscious world, the delivery of wood and pulp products is evolving to embrace sustainability and green practices. The demand for eco-friendly solutions in logistics is rising as industries recognize the importance of minimizing their carbon footprint. This shift is evident in the methods used for transporting wood and pulp products, focusing on reducing emissions, promoting recycling, and ensuring responsible sourcing. A critical aspect of delivering these products sustainably is optimizing transportation routes. By using advanced software and logistics planning, companies can minimize fuel consumption and greenhouse gas emissions. Efficient routing not only saves costs but also aligns with global efforts to combat climate change. Additionally, many companies are adopting electric or hybrid vehicles for their delivery fleets, significantly reducing air pollution and dependence on fossil fuels. Moreover, sustainable packaging plays a crucial role in the green delivery of wood and pulp products. Businesses are increasingly turning to biodegradable, recyclable, or reusable packaging materials.

These eco-friendly options help minimize waste and encourage a circular economy, where products are continuously reused and recycled rather than discarded. Such practices resonate with consumers who prioritize sustainability in their purchasing decisions. For instance, using recycled paper and cardboard for packaging not only reduces the demand for virgin materials but also supports the recycling industry, further minimizing environmental impact. Another essential element in delivering wood and pulp products sustainably is responsible sourcing. Companies are now emphasizing the importance of obtaining raw materials from sustainably managed forests. Certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) provide consumers with assurance that their products are sourced responsibly, helping to preserve biodiversity and protect ecosystems. This commitment to responsible sourcing also encourages better forest management practices, reducing illegal logging and promoting reforestation efforts.

Furthermore, the digital transformation in forest products logistics – Mobile, Alabama is contributing to more sustainable practices. Companies are leveraging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain to enhance transparency and efficiency throughout the supply chain. For instance, IoT sensors can monitor the condition of wood and pulp products during transportation, ensuring they are delivered in optimal condition, which can help reduce waste. Blockchain technology can also provide a transparent and traceable supply chain, enabling consumers to verify the sustainability claims of the products they purchase. Lastly, engaging with customers and educating them about the sustainability efforts in wood and pulp product delivery is vital. Companies can highlight their green practices through marketing campaigns, fostering a connection with environmentally conscious consumers. This not only enhances brand loyalty but also encourages a collective effort towards a more sustainable future. In conclusion, the delivery of wood and pulp products is undergoing a significant transformation towards sustainability, with a focus on optimizing logistics, adopting eco-friendly packaging, ensuring responsible sourcing, and leveraging technology.

Electric hoists are vital components in the construction and industrial sectors, enhancing crane kits to deliver optimal performance and safety. The integration of electric hoists into crane systems significantly improves lifting capabilities and operational efficiency, transforming the way materials and equipment are handled. By providing a reliable means of lifting heavy loads, electric hoists allow for the smooth operation of cranes, reducing manual labor and minimizing the risk of injury. This increased efficiency not only speeds up project timelines but also contributes to a safer work environment. One of the most compelling advantages of electric hoists is their ability to deliver consistent lifting power. Unlike manual hoists, which require significant physical strength and can lead to fatigue, electric hoists operate with the push of a button. This feature is particularly beneficial in environments where heavy loads need to be moved frequently or over long distances. The precision offered by electric hoists also enhances safety; operators can maneuver loads with greater accuracy, reducing the likelihood of accidents caused by dropped or improperly positioned items.

Safety is paramount in any industrial setting, and polipsto eléctrico de cadena are designed with numerous safety features that protect both workers and equipment. Most electric hoists are equipped with overload protection systems that prevent lifting beyond their rated capacity, mitigating the risk of equipment failure. Furthermore, many models include emergency stop buttons and limit switches, which ensure that the hoist does not operate beyond safe parameters. These features not only safeguard the machinery but also enhance the confidence of operators, allowing them to focus on their tasks without fear of unexpected malfunctions. The durability of electric hoists contributes to their effectiveness within crane kits. Built with high-quality materials that withstand the rigors of industrial environments, these hoists can endure the stresses of heavy lifting and harsh conditions. Regular maintenance, combined with the robust construction of electric hoists, ensures a long service life, which is crucial for businesses aiming to optimize their equipment investments.

Moreover, electric hoists can be customized to fit various crane configurations and lifting needs. This adaptability makes them suitable for a wide range of applications, from construction sites to manufacturing facilities. Businesses can choose hoists with different lifting capacities, speeds, and features tailored to their specific requirements. This versatility allows for the seamless integration of electric hoists into existing crane systems, enhancing overall functionality and productivity. In conclusion, the incorporation of electric hoists into crane kits represents a significant advancement in lifting technology, promoting safety and efficiency across various industries. Their ability to provide consistent lifting power, coupled with robust safety features and adaptability, makes electric hoists an indispensable asset in modern operations. As industries continue to prioritize safety and performance, the role of electric hoists in enhancing crane kits will only become more pronounced, paving the way for safer and more efficient workplaces. Investing in electric hoists is not merely a choice but a strategic decision that underscores a commitment to quality and safety in heavy lifting operations.

The demolishment of homes is an important service for cities to modernize and grow. The process involves the planning, getting permits, and executing the actual demolition.

The price of demolition is influenced by numerous factors, including the size and condition a building. Prior to beginning any project, it’s crucial to consider these factors.

House demolition prices

Prices for demolition vary based on the type of structure, dimensions and place of construction. The cost of demolition is comprised of the labor, permits and other equipment. The demolition cost will be higher for larger structures or those which have more complex construction. These factors will also affect the price per square feet.

In addition, the location of the property and its history will influence the demolition costs. Some old houses may contain asbestos or paint containing lead. It is essential to test these substances before the demolition process begins. There are additional costs involved with the removal of hazardous waste. In most cases, homeowners must obtain a permit to demolish their house, and certain regions require pre- or post-demolition inspections.

There are a variety of ways to tear down the house, such as manual and mechanical demolition. Mechanical demolition requires large machinery, making it more efficient and faster than manual demolition. Prices can vary from $4 to $15 per square foot. Removal of asbestos and foundations are also costly.

Despite the high cost of maintenance, HCMC continues to lose its historical properties in a fast-paced manner. A century-old house located in the Binh Thanh District, destroyed in the year 2000 to make way for a new construction. It was because of the city’s failure to establish a system for classifying heritage buildings. We hope that the city will take a lesson from this mistake and take measures to protect its cultural legacy.

Demolition services

Demolition is the process that involves the demolition of a structure. It can be accomplished entirely or in part, and it’s an essential component of any construction project. The demolition process is generally performed by experts who have specific equipment. You must choose a business that abides by strict guidelines for safety and environment. It’s also important to check the company’s reputation and chong vang nha reviews.

Demolition is the process that involves the demolition of a structure. It can be accomplished entirely or in part, and it’s an essential component of any construction project. The demolition process is generally performed by experts who have specific equipment. You must choose a business that abides by strict guidelines for safety and environment. It’s also important to check the company’s reputation and chong vang nha reviews.

A demolition company should also be able to manage the cleaning process. This means removing all garbage from the area and looking for materials to recycle wherever feasible. It also involves cleaning the site and ensuring that hazardous garbage is properly removed.

Many of the structures in HCMC are fragile due to their age, poor maintenance and outdated construction standards. They could pose a risk to the public, or even cause accidents. Expert demolition services ensure that structures with risks are removed which reduces the risk of accidents while also improving security for the public.

The wreck clearing worker could earn substantial profits by selling their work to scrap dealers. The wreckage could contain valuable items like wooden doors or iron rubble. These items are sold at VND10,000 per kilogram or around $0.22. In recent years, the wreck clearing industry has grown more professional.

Average unit price

HCMC is confronted with an ever-growing amount of demolition and construction waste. As a result, the city is spending an increasing amount of money for waste collection fees. Moreover, this fee is not sufficiently covered by the municipality’s revenue. The current waste management system of the city is fragmented, and it relies on private institutions to handle the waste. This is not eco efficient.

The price for demolition in HCMC is influenced by a number of factors, including the area and the size of the building, the condition of the structure, and the quality and type of the demolition services. In general, it is cheaper to demolish larger structures as opposed to smaller ones. However, the cost of a demolition project can be different based on the extent and complexity of the work. A demolition project that has extra complexity, for instance the preservation of a portion of the building, or safety concerns could cost more than a simple renovation.

A recent report from C&W Vietnam suggests that house prices in the primary market are increasing due to a shortage in supply. However, these high prices have not translated to the secondary market, where apartment prices have remained stable. In addition, the rate of absorption of villas and townhouses has dropped considerably. The reason behind this is the fact that developers tend to build developments with high rises due to their higher profits. The limited number of new apartments available is a result of this.

District-wise demolition prices

In a typical demolition, the cost of cleaning up debris can range between $500 and $2000. This is the removal and disposal of hazardous waste, such as asbestos, lead-based paint and chemical. Recycling these materials could help homeowners save money, decrease the amount of waste in landfills, and can help offset demolition costs. A successful demolition job requires careful planning and an eye on safety.

A district-wise analysis of the costs for demolition in HCMC is necessary to identify the variables that impact these costs. The condition of the building to be demolished is an important determinant. The cost of demolition tends to be less expensive for structures in good condition, but may be more expensive for buildings that have structural issues or historical significance. In addition, the choice between partial or total demolition could have a significant impact on costs.

The price of demolition work depends on many aspects, including the size and location of the construction. The cost of demolition is more expensive in cities due to the rising costs for permits and labor. Rural areas are less expensive in terms of demolition costs. There are certain trade-offs that come with moving to the country, such as longer commute times, fewer public transportation options, and lesser infrastructure.

The HCMC city government is looking at ways to improve its environment, such as reducing the use of landfills. This will require a transition towards a circular economy as well as the development recycling facilities. Moreover the city is creating strategies to help the city become more suburban and to maintain its high degree of mobility for individuals.

Floating dock bridges represent a pioneering solution in sustainable design, merging functionality with environmental stewardship. These innovative structures, often seen in marinas and waterfront developments, offer a range of eco-friendly advantages that contribute to a healthier ecosystem and a reduced carbon footprint. One of the most significant benefits of floating dock bridges is their ability to adapt to changing water levels. Traditional fixed bridges can disrupt natural water flow and habitats, but floating designs move with the tides and seasonal fluctuations, minimizing their impact on aquatic ecosystems. This adaptability not only preserves local wildlife but also protects the integrity of the bridge itself from potential damage caused by shifting waters. In terms of materials, many floating dock bridges are constructed using sustainable resources. Modern designs often incorporate recycled or reclaimed materials, such as plastic composites, which are durable and resistant to the corrosive effects of water. By utilizing these materials, floating docks reduce the need for new resources and minimize waste.

Additionally, what is a floating bridge some manufacturers are now exploring bio-based materials, which can further enhance the sustainability of these structures. The energy efficiency of floating dock bridges is another eco-friendly advantage. Many of these designs integrate renewable energy solutions, such as solar panels, which can power lighting and other systems on the dock. This not only reduces reliance on fossil fuels but also promotes a cleaner energy ecosystem. By generating their own power, floating dock bridges can contribute to a more sustainable marina or waterfront area, aligning with broader environmental goals. Moreover, floating dock bridges facilitate improved water quality. By providing a stable platform for recreation and transportation, they encourage responsible use of waterways while minimizing erosion and disruption to surrounding habitats. The design can also include features such as permeable surfaces that allow rainwater to seep through, reducing runoff and promoting groundwater recharge. This approach helps maintain the natural hydrology of the area and supports local flora and fauna.

Socially, floating hiseadock bridges enhance community engagement with nature. They create accessible spaces for recreational activities such as fishing, kayaking, and boating, fostering a connection between people and their natural surroundings. By promoting outdoor activities, these structures encourage environmental awareness and stewardship among community members, driving home the importance of preserving aquatic ecosystems. In conclusion, floating dock bridges exemplify the principles of sustainable design by harmonizing human needs with ecological preservation. Their ability to adapt to environmental conditions, utilize sustainable materials, harness renewable energy, improve water quality, and promote community engagement underscores their significant eco-friendly advantages. As urban areas continue to expand and the demand for waterfront access grows, floating dock bridges offer a promising solution that prioritizes sustainability while enhancing the quality of life for residents and visitors alike. Through thoughtful design and innovation, these structures can lead the way towards a more sustainable future.

Digital signage has emerged as a transformative tool for schools, revolutionizing the way information is disseminated across campuses. As educational institutions seek more effective means to communicate important announcements, digital signage provides a dynamic and engaging solution that can enhance the overall school environment. By integrating modern technology into their communication strategies, schools can ensure that messages reach students, staff, and parents promptly and effectively. One of the primary benefits of digital signage is its ability to display real-time information. Unlike traditional bulletin boards or paper flyers that require time-consuming updates and often become outdated quickly, digital displays can be easily modified to reflect the most current announcements. Whether it is a last-minute schedule change, an upcoming event, or emergency notifications, digital signage allows for immediate updates that can be broadcast across multiple screens throughout the campus. This ensures that everyone is informed and can react swiftly to important news.

Moreover, digital signage can be used to promote school spirit and community engagement. Schools can showcase student achievements, highlight extracurricular activities, and celebrate special events through eye-catching graphics and animations. By featuring photos and videos of students participating in sports, arts, and other activities, digital signage helps to foster a sense of pride and belonging within the school community. This not only encourages student involvement but also strengthens the connection between the school and parents, who are more likely to engage with the school when they see their children’s accomplishments being celebrated. Another advantage of digital signage is its versatility in content delivery. Schools can utilize these displays to share a wide range of information, including academic schedules, lunch menus, and important deadlines. Furthermore, digital signage can be programmed to rotate different messages throughout the day, ensuring that a variety of announcements are seen by students during passing periods or lunch breaks. This adaptability allows schools to tailor their messages to specific audiences, whether that is students, staff, or visitors.

Additionally, education digital signage can play a crucial role in enhancing safety protocols within schools. In the event of an emergency, digital displays can quickly convey critical information, guiding students and staff to safety. They can also be used to display important health and safety reminders, such as hygiene practices or social distancing guidelines. This capability not only supports the well-being of the school community but also reinforces the institution’s commitment to safety. In conclusion, digital signage represents a smart solution for school-wide announcements, addressing the communication challenges faced by educational institutions today. By leveraging the power of technology, schools can ensure that their messages are seen, heard, and acted upon. From promoting school spirit to enhancing safety protocols, digital signage offers a myriad of benefits that can significantly improve the overall educational experience. As schools continue to evolve in the digital age, investing in digital signage will undoubtedly be a key component of effective communication strategies.

Molecular sieves are indispensable materials in various industrial applications, including gas separation, catalytic processes, and environmental control. These highly porous materials, typically made from aluminosilicates or zeolites, are designed to selectively adsorb molecules based on size, shape, or chemical properties. Recent technological advancements are revolutionizing the production and efficiency of molecular sieves, driving down costs and enhancing performance across a multitude of applications. One significant breakthrough in molecular sieve production is the development of advanced synthesis techniques. Traditional methods often involve complex and time-consuming processes, including high-temperature treatments and long crystallization times. However, researchers have recently introduced innovative approaches such as rapid crystallization methods and microwave-assisted synthesis. These techniques not only reduce production time but also improve the uniformity and quality of the molecular sieves. Microwave-assisted synthesis, for instance, accelerates the crystallization process by providing uniform and controlled heating, which results in higher yield and better structural integrity of the sieves.

Another notable advancement is the integration of nanotechnology into molecular sieve production. The incorporation of nanoparticles and nanostructures has led to the creation of new types of molecular sieves with enhanced properties. For example, nanoparticles can be used to fine-tune the pore sizes and improve the selectivity of the sieves. Additionally, nanomaterials can enhance the mechanical strength and thermal stability of the sieves, what is a dessicant making them more suitable for demanding applications. This approach not only extends the lifespan of the sieves but also expands their applicability to more challenging environments. The optimization of molecular sieve production has also benefited from advancements in automation and process control. Modern production facilities are increasingly utilizing automated systems and real-time monitoring to streamline operations and ensure consistent quality. These systems enable precise control over synthesis conditions, such as temperature, pressure, and reactant concentrations. The use of advanced sensors and data analytics allows for continuous adjustment of parameters, minimizing variability and improving overall efficiency.

This shift towards automated and data-driven production processes is reducing human error and operational costs while enhancing the reproducibility of the molecular sieves. Furthermore, there is a growing emphasis on the sustainability of molecular sieve production. Recent research is focused on developing eco-friendly synthesis methods and recyclable materials. For instance, researchers are exploring the use of alternative, less hazardous chemicals and energy-efficient processes. Additionally, efforts are being made to create Jalon molecular sieves from renewable resources and to design them for easier recycling at the end of their life cycle. These initiatives not only contribute to environmental conservation but also align with the increasing demand for sustainable industrial practices. the latest technological breakthroughs in molecular sieve production are driving significant improvements in efficiency, performance, and sustainability. Advances in synthesis techniques, nanotechnology, automation, and eco-friendly practices are shaping the future of this critical material.

Oxygen cylinders are critical for medical and industrial applications, but their disposal requires careful attention to environmental impacts. These cylinders are typically made of metals like steel or aluminum, both of which are recyclable. However, if not properly handled, discarded oxygen cylinders can cause serious environmental hazards. The first step in eco-friendly disposal is ensuring the cylinder is empty and decommissioned. An oxygen cylinder that still contains gas may pose a fire or explosion risk. Additionally, some facilities offer specialized disposal services that adhere to environmental safety standards, reducing the risks of improper handling. One of the primary concerns with oxygen cylinder disposal is the risk of explosion. Compressed oxygen cylinders can become highly pressurized, and if not handled correctly, they can cause dangerous explosions. To prevent such incidents, it is essential to follow proper procedures for emptying and depressurizing the cylinders before disposal. Many manufacturers and suppliers offer services to safely decommission and dispose of old or unused cylinders.

Once decommissioned, recycling is the most sustainable disposal option. Many scrap metal recyclers accept oxygen cylinders, provided they are depressurized and have no remaining contaminants. Recycling reduces the demand for raw materials and minimizes energy consumption during the manufacturing process. Another advantage of recycling is the significant reduction of waste sent to landfills. When left in landfills, metal cylinders can take centuries to decompose, leaching harmful substances into the soil and water systems, and negatively impacting ecosystems. To promote responsible disposal practices, it is beneficial for organizations and individuals to engage in proactive measures. This includes establishing protocols for the safe handling, storage, and disposal of oxygen cylinders. Educating staff and users about proper disposal methods and providing easy access to disposal services can further enhance safety and environmental protection.

Reuse programs can offer a green solution to oxygen cylinder disposal. Some manufacturers and companies refurbish cylinders, giving them a second life rather than discarding them. These programs ensure that fewer new cylinders need to be manufactured, further reducing the environmental footprint. Hospitals and industrial facilities should prioritize working with licensed professionals who specialize in eco-friendly disposal methods. To buy oxygen tanks online, individuals and businesses contribute to reducing the environmental impact of oxygen cylinders, preserving resources, and protecting the planet for future generations. The disposal of oxygen cylinders requires careful consideration to ensure environmental protection and safety. By following proper procedures for depressurizing, recycling, and adhering to local regulations, we can minimize the environmental impact and reduce the risks associated with oxygen cylinder disposal. Responsible practices not only help prevent potential hazards but also contribute to a more sustainable and environmentally friendly approach to managing these essential tools.

In the ever-evolving field of mineral processing, the advent of advanced equipment has marked a significant leap forward, enhancing both safety and productivity in mining operations. The integration of state-of-the-art technology has transformed traditional practices, ensuring that operations are not only more efficient but also safer for workers and the environment. One of the foremost advancements in mineral processing is the development of automated and remotely operated machinery. These innovations allow for the operation of processing equipment from a safe distance, significantly reducing the risk of accidents and injuries. For example, automated crushers and grinders, which once required direct human oversight, can now be monitored and controlled through sophisticated control systems. This shift not only minimizes human exposure to hazardous conditions but also improves precision and consistency in processing.

Another critical advancement is the enhancement of process monitoring and control systems. Modern mineral processing equipment is equipped with real-time sensors and data analytics capabilities that provide continuous feedback on the operational status of machinery. These systems can detect anomalies, predict maintenance needs, and optimize processing parameters to ensure maximum efficiency. By leveraging big data and machine learning algorithms, these technologies help in preemptively addressing potential issues before they escalate into significant problems, thereby reducing downtime and enhancing productivity and Recommended Site www.minejxsc.com. In addition to automation and advanced monitoring, the development of more efficient separation technologies has revolutionized the mineral processing industry. Techniques such as advanced flotation systems and high-efficiency classifiers enable more precise separation of valuable minerals from waste material. This not only improves the yield of valuable resources but also reduces the volume of waste generated, leading to more sustainable practices. The use of these technologies aligns with the industry’s growing emphasis on environmental stewardship and resource conservation.

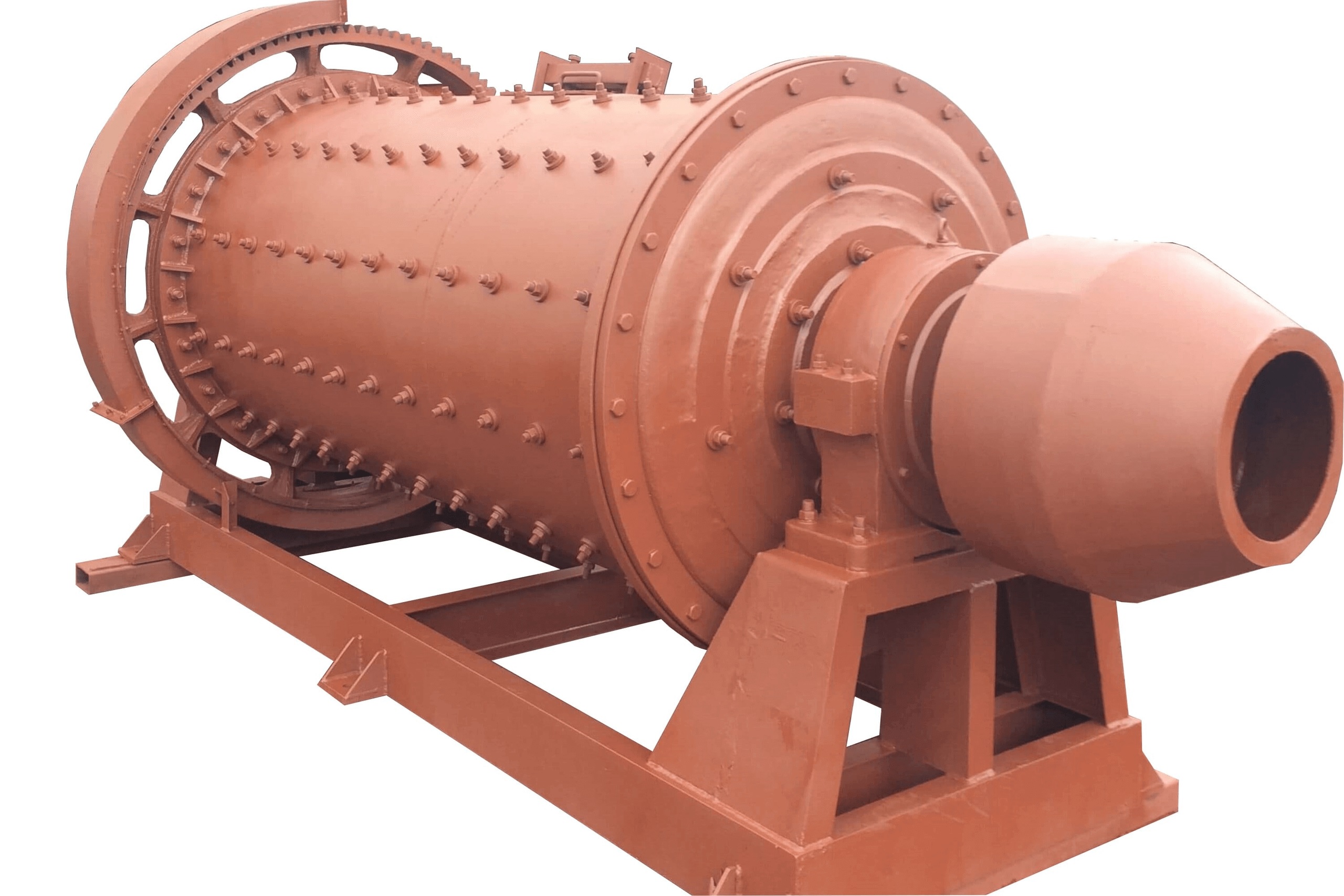

Safety enhancements have also been a focal point in the evolution of mineral processing equipment. Modern machinery is designed with robust safety features, including advanced hazard detection systems, emergency shut-off mechanisms, and ergonomic controls. These features are intended to protect workers from potential hazards such as equipment malfunctions or unsafe operating conditions. Additionally, the implementation of virtual reality VR and simulation training programs allows operators to gain hands-on experience in a controlled environment, further reducing the risk of accidents in real-world operations. The integration of sustainable practices in mineral processing is another area of significant progress. Advanced equipment now incorporates energy-efficient technologies and systems that reduce the environmental footprint of mining operations. Innovations such as energy-efficient motors, improved material handling systems, and what is a ball mill waste heat recovery solutions contribute to lower energy consumption and reduced greenhouse gas emissions. This focus on sustainability not only supports regulatory compliance but also enhances the industry’s social license to operate.

Triple offset butterfly valve manufacturers play a crucial role in advancing industrial automation by delivering highly specialized components that enhance the efficiency, reliability, and control of automated systems. These valves, known for their sophisticated design and operational precision, are integral to modern industrial processes where automation is increasingly prevalent. The triple offset butterfly valve, distinguished by its unique design features, addresses the demands of high-performance applications in various industries such as oil and gas, chemical processing, power generation, and water treatment. The term triple offset refers to the three key design aspects: the shaft offset, the seat offset, and the cone offset. These offsets contribute to the valve’s ability to provide a tight shut-off, reduce torque, and extend the valve’s lifespan. By incorporating these design principles, manufacturers create valves that are not only robust and durable but also capable of handling extreme conditions and high pressures, making them ideal for automated systems that require precision and reliability.

In the realm of industrial automation, the integration of triple offset butterfly valves plays a significant role in enhancing system performance. These triple offset butterfly valve manufacturers can be seamlessly integrated with automation systems, including programmable logic controllers PLCs and distributed control systems DCS. This integration allows for precise control over fluid flow, pressure, and temperature, which is essential for maintaining optimal operating conditions and ensuring the safety and efficiency of industrial processes. Moreover, the advanced technology employed by manufacturers in designing and producing these valves contributes to reducing operational costs and downtime. Triple offset butterfly valves are designed to offer minimal friction and wear, resulting in lower maintenance requirements and longer service intervals. This reliability is particularly valuable in automated systems where downtime can lead to substantial financial losses and operational disruptions. By reducing the need for frequent maintenance and replacements, these valves support the overall goal of industrial automation: maximizing uptime and productivity.

Another important aspect of the role played by triple offset butterfly valve manufacturers is their contribution to the development of smart valve technologies. Modern Dombor triple offset valves can be equipped with sensors and actuators that enable real-time monitoring and remote control. This capability allows for proactive maintenance and precise adjustments, further enhancing the automation process. For example, sensors can provide feedback on valve performance, allowing for early detection of potential issues before they escalate into major problems. Actuators can adjust valve positions based on real-time data, ensuring that the system remains within desired parameters and optimizing performance. In addition to these technical advancements, manufacturers of triple offset butterfly valves also contribute to the industry by focusing on customization and flexibility. They offer a range of options and configurations to meet the specific needs of different applications. This adaptability ensures that automated systems can be tailored to suit particular requirements, enhancing their effectiveness and efficiency. As industrial processes continue to evolve and demand greater precision and efficiency, the role of these manufacturers in driving technological advancements and supporting automation will remain increasingly vital.

As electric vehicles EVs continue to surge in popularity, their role extends far beyond reducing emissions from the transportation sector. One of the lesser-known but impactful benefits of EVs is their potential to support the integration of renewable energy sources into our power grids. This synergy between EV chargers and renewable energy can significantly enhance the efficiency and stability of energy systems, paving the way for a cleaner and more resilient energy future.

Flexible Energy Demand

EV chargers contribute to renewable energy integration by providing flexible energy demand. Unlike traditional vehicles that require consistent refueling, EVs can be charged at different times, making their energy consumption more adaptable to the availability of renewable energy. For instance, during periods of high solar or wind generation, when renewable energy production exceeds grid demand, EVs can be charged, thereby absorbing excess power. This flexibility helps stabilize the grid and prevents the waste of surplus renewable energy.

Vehicle-to-Grid V2G Technology

One of the most promising advancements in EV technology is Vehicle-to-Grid V2G integration. V2G allows EVs to not only draw power from the grid but also return stored energy back to it. During times of peak demand or when renewable generation is low, EVs can discharge energy stored in their batteries to support the grid. This bidirectional flow of energy helps balance supply and demand, reduces reliance on fossil fuels, and enhances grid reliability and click here https://www.beny.com/it/.

Smart Charging Infrastructure

Smart charging infrastructure plays a crucial role in aligning EV charging with renewable energy availability. Smart chargers can be programmed to operate when renewable energy generation is at its peak, such as during sunny afternoons or windy nights. These chargers use real-time data to optimize charging schedules, reducing the strain on the grid and making better use of renewable resources. Additionally, smart charging can be coordinated with energy markets and grid operators to provide ancillary services such as frequency regulation and demand response.

Energy Storage Integration

EVs themselves act as mobile energy storage units. When coupled with home solar panels and residential battery systems, EVs can store excess solar energy generated during the day and use it for charging during the night or for home consumption. This integration of EVs with home energy systems enhances energy self-sufficiency and reduces reliance on grid electricity, especially during periods of high demand or low renewable generation.

Enhanced Grid Resilience

The distributed nature of EV charging and V2G technology can enhance the resilience of the power grid. By decentralizing energy sources and storage, EVs reduce the vulnerability of the grid to single points of failure. In the event of a power outage or grid disruption, EVs equipped with V2G technology can provide backup power to homes or critical infrastructure, ensuring continued operation and reducing the impact of disruptions.

Beny EV chargers are more than just devices for powering vehicles they are vital components in the transition to a renewable energy future. By offering flexible energy demand, supporting V2G technology, utilizing smart charging infrastructure, integrating with energy storage systems, enhancing grid resilience, and promoting renewable energy adoption, EV chargers play a significant role in making our energy systems more sustainable and efficient.

Recent Posts

- Quiet Efficient and Stylish Mini Split AC for Any Room

- Proven Strategies That Drive Success for Business Owners and Investors

- Optimising Dental SEO with Collaborative Content Creation

- Gain Exclusive Market Insights at This Industry-Leading Trade Show

- Protect Your Car’s Interior and Enhance Aesthetics with Advanced Window Tinting